洛阳松导感应加热科技有限公司

联系方式:15038554363

24小时技术热线:15038554363

邮 箱:1390003299@qq.com

厂址:河南省洛阳市洛新工业园区

名称:30t感应熔炼炉

价格:0

1 ,设备概述

感应熔炼炉 是一种高效的冶炼设备,通过电磁感应加热熔化废钢。能量转换过程是电磁加热,特别是整流变压器输出的工频电源转换成与AC-DC-AC负载所需频率相匹配的单相交流电源。模式,并在炉中的废钢中产生。高强度磁场,炉内废钢在磁场作用下产生强电场,形成内部涡流,从而形成熔化自身的热源。这种在电荷内部自身产生热能的加热方法是一种有效的熔化方式。

我公司生产的感应熔炼炉具有以下特点:

1输入电压高,输出电压高。对于本程序30t 感应熔炼炉的额定容量,我公司按照1750V进线电压规范设计,传感器负载输出电压标称值为6300V。

2熔化速度快。达到额定设计吨位攻丝量,连续热炉熔炼时间控制在75分钟左右。

3吨钢具有低能耗。比其他厂家设备低5%,优于GB / T30839.31-2014“工业电加热设备能耗:中频无心感应熔炼炉” 的一流标准。

4数字化,集成化和高度自动化。该公司的电源系统控制板是一种数字芯片型控制板。功放板是集成功率放大,漏洞检测和输出的集成控制板。冶炼管理系统以S7-300PLC +高配备主机为硬件,STEP7 + WINCC为软件,实现对整个设备的监控和管理。

2 ,技术方案和技术参数

2.1 ,技术方案

对于 该项目的30t 感应熔炼炉,公司采用以下技术方案:

▷ 设备配置模式:一台电动两炉。炉子通常是熔炼的,炉子用于炉子维护。

▷ 切换模式:炉子开关的机械变化。

▷ 送料方式:平台上的液压送料小车在炉后送料。

▷ 钢攻丝方法:液压倾斜炉,攻丝喷嘴和攻丝钢攻丝。

▷ 变压器:使用单个24脉冲整流变压器。

▷ 自动控制系统:硬件采用S7-300配置工业控制计算机。

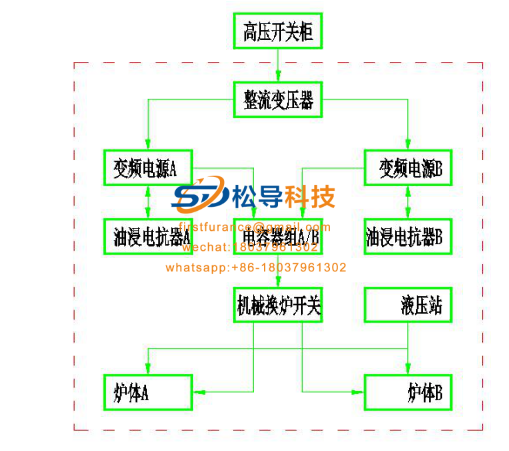

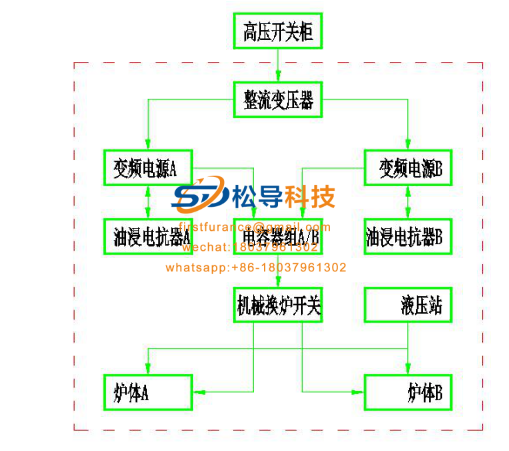

设备系统图如下:

高压开关柜:高压开关柜

整流变压器:整流变压器

变频电源:变频电源

油浸电抗器:油浸电抗器

电容器组:电容器组

机械换炉开关:机械炉改变 开关

炉体:炉体

液压站:液压站

2.2 , Ť 技术参数

|

项目 |

单元 |

参数 |

备注 |

|||

|

基本参数 |

||||||

|

额定容量 |

Ť |

三十 |

|

|||

|

最大容量 |

Ť |

40 |

取决于炉子的建造过程 |

|||

|

额定出 钢 温度 |

℃ |

1600 |

|

|||

|

融化时间 |

分 |

75±5% |

注1 |

|||

|

熔化率 |

吨/小时 |

23-25 |

注1 |

|||

|

能量消耗 |

KW ·H / t |

500±5% |

注1 |

|||

|

变频功率 |

||||||

|

额定功率 |

KW |

16000 |

|

|||

|

入口电压 |

V |

1750 |

Mid档 |

|||

|

整改模式 |

P |

24 |

|

|||

|

M id-frequency |

赫兹 |

150 |

|

|||

|

Ø 本安输出电压 |

V |

6300 |

|

|||

|

|

循环模式 |

|

关闭(内部和外部双循环) |

C ooling水 |

||

|

压力 |

兆帕 |

0.1-0.12 |

Ø utlet≤0.05 |

|||

|

流 |

吨/小时 |

260 |

|

|||

|

我温度 |

℃ |

≤35 |

|

|||

|

温度升高 |

℃ |

≤8 |

|

|||

|

感应熔炼炉 身 |

||||||

|

电感器内径 |

毫米 |

φ1900 |

|

|||

|

电感高度 |

毫米 |

2900 |

|

|||

|

电感电压 |

V |

6300 |

|

|||

|

|

循环模式 |

|

关闭(内部和外部双循环); 可以选择打开 |

C ooling水 |

||

|

压力 |

兆帕 |

0.2-0.3 |

|

|||

|

流 |

吨/小时 |

450 |

小号英格尔炉300 |

|||

|

我温度 |

℃ |

≤40 |

|

|||

|

温度升高 |

℃ |

≤12 |

|

|||

|

^ h ydraulic 小号ystem |

||||||

|

工作压力 |

兆帕 |

12 |

|

|||

|

液压介质 |

|

阻燃抗磨液压油 N68 |

|

|||

|

圆柱直径 |

毫米 |

280 |

|

|||

|

整流变压器(单组24脉冲,带静电屏蔽和二次低压继电保护) |

||||||

|

ř ated容量 |

KVA |

21000 |

|

|||

|

参考模型 |

|

ZSSP-二十二分之二万一 /1.75*4 |

|

|||

|

第一线电压 |

KV |

22 |

暂时参考 |

|||

|

二线电压 |

V |

1750 |

Mid档 |

|||

|

阻抗电压 |

|

> 10% |

|

|||

|

调整电压模式 |

|

无励磁电压调节 |

|

|||

|

冷却模式 |

|

强制油循环水冷却 |

|

|||

|

|

循环模式 |

|

关闭(内部和外部双循环) |

C ooling水 |

||

|

压力 |

兆帕 |

0.1-0.12 |

|

|||

|

流 |

吨/小时 |

60 |

|

|||

|

我温度很高 |

℃ |

≤35 |

|

|||

|

Ť emperature加薪 |

℃ |

≤8 |

|

|||

注1:

用户工作条件:

废钢产量≥97%,热,连续,轻薄的材料必须包装成煤球,大型材料切割,使用压力机械手。除了保温和排渣时间外,还要根据熔融钢的实际称重。

1,Equipment overview

Induction melting furnace is an efficient smelting equipment that melts scrap steel by electromagnetic induction heating. The energy conversion process is electro-magnetic-electric-heating, in particular, the power frequency power supply outputted by the rectifier transformer is converted into a single-phase AC power source matching the required frequency of the load in an AC-DC-AC mode, and is generated in the steel scrap in the furnace. High-strength magnetic field, the steel scrap in the furnace induces a strong electric field under the action of a magnetic field and forms an internal eddy current, thereby forming a heat source to melt itself. This heating method of generating thermal energy by itself inside the charge is an efficient way of melting.

The Induction melting furnace produced by our company has the following characteristics:

1 The input voltage is high and the output voltage is high. For the rated capacity of this program 30t Induction melting furnace, our company is designed according to the 1750V incoming line voltage specification, and the sensor load output voltage is nominally 6300V.

2 High melting rate. The rated design tonnage tapping amount is reached, and the continuous hot furnace smelting time is controlled at about 75 minutes.

3 tons of steel has low energy consumption. It is 5% lower than other manufacturers' equipment, which is better than the first-class standard in GB/T30839.31-2014 "Industrial electric heating device energy consumption: medium frequency centerless Induction melting furnace".

4 Digital, integrated, and highly automated. The company's power system control board is a digital chip type control board. The power amplifier board is an integrated control board integrating power amplification, vulnerability detection and output. The smelting management system realizes the monitoring and management of the entire equipment by using S7-300PLC+ high-equipped host as hardware and STEP7+WINCC as software.

2,Technical solutions and technical parameters

2.1, Technical solutions

For the 30t Induction melting furnace of this project, the company adopts the following technical solutions:

▷ Equipment configuration mode: one electric two furnaces. A furnace is normally smelted, and a furnace is used for furnace maintenance.

▷ Switching mode: mechanical change of furnace switch.

▷ Feeding method: The hydraulic feeding trolley on the platform is fed after the furnace.

▷The method of steel tapping: hydraulic tilting furnace, tapping nozzle and tapping steel tapping.

▷ Transformer: A single 24-pulse rectifier transformer is used.

▷Automatic control system: The hardware adopts S7-300 and configures industrial control computer.

The equipment system diagram is as follows:

高压开关柜:High voltage switchgear

整流变压器:Rectifier transformer

变频电源:Frequency change power

油浸电抗器:Oil immersion reactor

电容器组:Capacitor bank

机械换炉开关:Mechanical furnace change switch

炉体:Furnace body

液压站:Hydraulic station

2.2、Technical parameters

|

ITEM |

UNIT |

PARAMETER |

REMARK |

|||

|

Basic parameters |

||||||

|

Rated capacity |

t |

30 |

|

|||

|

Max capacity |

t |

40 |

Depending on the furnace building process |

|||

|

Rated tapping temperature |

℃ |

1600 |

|

|||

|

Melting time |

min |

75±5% |

Note1 |

|||

|

Melting rate |

t/h |

23-25 |

Note1 |

|||

|

Power consumption |

KW·H/t |

500±5% |

Note1 |

|||

|

Frequency change power |

||||||

|

Rated power |

KW |

16000 |

|

|||

|

Inlet voltage |

V |

1750 |

mid-gear |

|||

|

Rectification mode |

P |

24 |

|

|||

|

Mid-frequency |

HZ |

150 |

|

|||

|

Output voltage |

V |

6300 |

|

|||

|

|

Cyclic mode |

|

Closed (internal and external double cycle) |

Cooling water |

||

|

Pressure |

MPa |

0.1-0.12 |

Outlet≤0.05 |

|||

|

Flow |

t/h |

260 |

|

|||

|

Inlet temperature |

℃ |

≤35 |

|

|||

|

Temperature raise |

℃ |

≤8 |

|

|||

|

Induction melting furnace body |

||||||

|

Inner diameter of inductor |

mm |

φ1900 |

|

|||

|

Height of inductor |

mm |

2900 |

|

|||

|

Voltage of inductor |

V |

6300 |

|

|||

|

|

Cyclic mode |

|

Closed (internal and external double cycle) ;Can choose to open |

Cooling water |

||

|

Pressure |

MPa |

0.2-0.3 |

|

|||

|

Flow |

t/h |

450 |

Single furnace 300 |

|||

|

Inlet temperature |

℃ |

≤40 |

|

|||

|

Temperature raise |

℃ |

≤12 |

|

|||

|

Hydraulic system |

||||||

|

Working pressure |

MPa |

12 |

|

|||

|

Hydraulic medium |

|

Flame retardant anti-wear hydraulic oil N68 |

|

|||

|

Diameter of cylinder |

mm |

280 |

|

|||

|

Rectifier transformer (single set 24 pulses, with electrostatic shielding and secondary low voltage relay protection) |

||||||

|

Rated capacity |

KVA |

21000 |

|

|||

|

Reference model |

|

ZSSP-21000/22 /1.75*4 |

|

|||

|

First line voltage |

KV |

22 |

Reference temporarily |

|||

|

Second line voltage |

V |

1750 |

mid-gear |

|||

|

Impedance voltage |

|

>10% |

|

|||

|

Adjust voltage mode |

|

Non-excitation voltage regulation |

|

|||

|

Cooling mode |

|

Forced oil circulation water cooling |

|

|||

|

|

Cyclic mode |

|

Closed (internal and external double cycle) |

Cooling water |

||

|

Pressure |

MPa |

0.1-0.12 |

|

|||

|

Flow |

t/h |

60 |

|

|||

|

Intlet temperature |

℃ |

≤35 |

|

|||

|

Temperature raise |

℃ |

≤8 |

|

|||

NOTE 1:

Users working conditions:

Scrap steel yield ≥97%, hot, continuous, light and thin materials must be packaged into briquettes, large material cutting, with the use of pressing manipulator. Except for heat preservation and slag discharge time, based on the actual weighing of molten steel.

手 机:15038554363