洛阳松导感应加热科技有限公司

联系方式:15038554363

24小时技术热线:15038554363

邮 箱:1390003299@qq.com

厂址:河南省洛阳市洛新工业园区

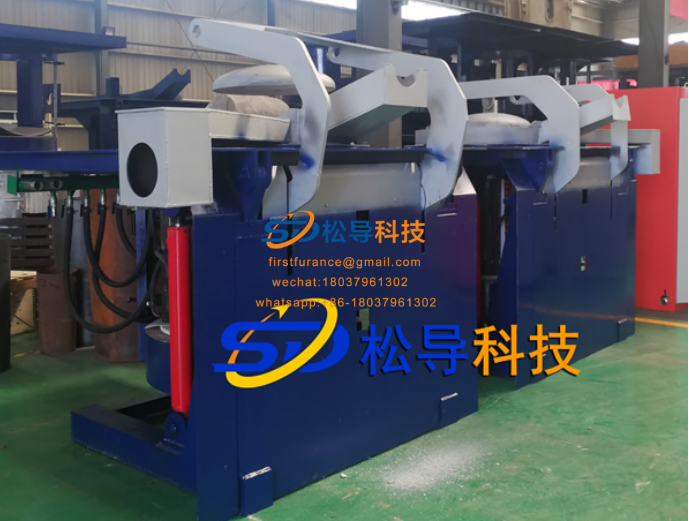

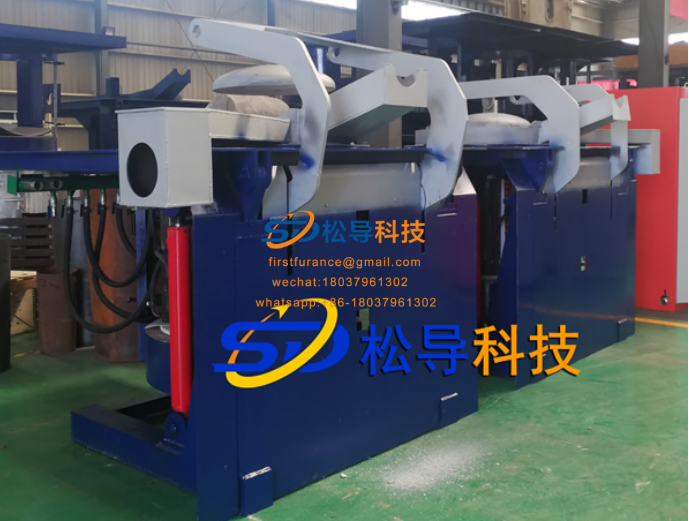

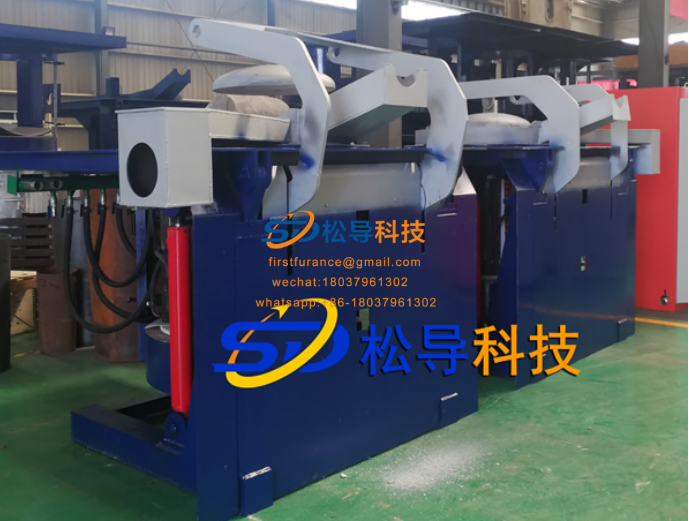

名称:感应熔炼炉

价格:0

1 ,感应熔炼炉是将三相变频器单元电流转换成中频的单相电流,由金属引起的电磁场,涡流损耗,达到热熔的目的。用于黑色或有色金属及合金材料(如钢,铜,铝,锌和铅)的熔化,加热和保温。主要用于金属铸造,炼钢行业。

钢壳炉体包括: 钢壳炉体 ,感应线圈和磁场屏蔽系统。三大部分

配置部分包括: 自动烤箱功能 ,旋风式防尘罩,换炉开关,防摔装置,防漏炉报警装置,炉衬快速释放机构, 炉体称重系统 。

★旋风除尘罩:吸尘效果更好,占用空间小,可前后倾斜,任意位置。适用于铸造厂的全自动进料和卸料操作。

★换向开关:转换开关是一种用于中频电炉的电动快换开关:操作简便,安全可靠,使用方便,缩短了炉子切换时间,提高了工作效率,降低了工人的劳动强度,并且能够容易实现中频电源切换到保温炉体和熔化炉,具有很大的实用性。

★防磨炉报警功能:双重防磨炉报警功能,采用差动电流模式和直流注入式双组合检测。为炉系统提供极其可靠的防漏保护,并全面快速保护任何接地故障。检测系统具有预警功能。当炉衬减薄到一定程度时,将提前发出警报灯报警,提醒用户将达到衬里的使用寿命,并提前预测安全生产的目的。解决客户的麻烦,因为它已被使用,直到它无法打开,炉子有材料,不能继续融化。

★炉衬结构:炉温冷却至400 ℃ 以下后 ,炉体转至 90 度,起重机抬起并推出,缸体连接法兰置于底部预先设计的钢轨内炉体启动液压泵站。,轻松推出衬里。降低工作强度,提高工作效率。

中频功率性能特点:

根据电源的大小,感应熔炼炉可选用 KGPS 中频电源 , 12 脉冲波中频电源 和 24 脉冲波中频电源 ,也可选择 IGBT 中频电源 。中频电源的控制模式可以设计为本地控制,触摸屏控制,远程控制和计算机控制。

感应熔炼炉技术参数:

|

感应熔炼炉型号 |

GWGR - 1 |

GWGR -2 |

GWGR -3 |

|

额定容量 (T) |

1 |

2 |

3 |

|

功率( KW ) |

1000 |

1500 |

2000 |

|

频率( Hz ) |

1000 |

800 |

800 |

|

额定温度(°C) |

1650 |

1650 |

1650 |

|

熔化时间(分钟 / 炉) |

60 |

60 |

80 |

|

功耗( 千瓦时/吨 ) |

550〜600 |

550〜600 |

550〜600 |

|

冷却水压力 |

0.2~0.3M p a |

0.2~0.3M p a |

0.2~0.3M p a |

|

进水温度(°C) |

≤ 35 |

≤ 35 |

≤ 35 |

|

出水温度(°C) |

≤ 55 |

≤ 55 |

≤ 55 |

相关产品:

1 , an induction melting furnace is a three-phase frequency inverter unit currents into a single-phase current of the intermediate frequency, the electromagnetic field induced by the metal, the eddy current loss, and achieve the purpose of heat melting. It is used for melting, heating and heat preservation of black or non-ferrous metals and alloy materials such as steel, copper, aluminum, zinc and lead. Mainly used in metal casting, steelmaking industry.

2 , furnace structure ( steel shell furnace and aluminum shell furnace )

Aluminum shell furnace body; aluminum shell, induction coil , reducer

The steel shell furnace body includes: a steel shell furnace body , an induction coil, and a magnetic field shielding system . Three major parts

The configuration parts include: automatic oven function , cyclone type dust cover , furnace change switch, anti-drop device, leakproof furnace alarm device, furnace lining quick-release mechanism, furnace body weighing system .

★ Cyclone dust hood: It has better vacuuming effect, takes up less space, can tilt forward and backward and stay in any position. Applicable to the fully automated feeding and discharging operations of the foundry.

★ Changer switch: The changeover switch is an electric quick change switch used in medium frequency electric furnace: easy to operate, safe and reliable, easy to use, shortens the time of furnace switching, improves efficiency, reduces labor intensity of workers, and can It is easy to realize the switching of the intermediate frequency power supply to the holding furnace body and the melting furnace, which has great practicality.

★ Anti-wearing furnace alarm function : double anti-wearing furnace alarm function, using dual combination detection of differential current mode and DC injection type. Provides an extremely reliable leak protection for the furnace system and all-round rapid protection of any ground fault. The detection system has an early warning function. When the furnace lining is thinned to a certain extent, an alarm light alarm will be made in advance to remind the user that the life of the lining will be reached, and the purpose of safe production is predicted in advance. Solve the trouble of the customer because it has been used until it can not be turned on, and the furnace has material and cannot continue to melt.

★ Furnace lining structure: Once the furnace temperature is cooled to below 400 °C, the furnace body is turned to 90 degrees, the crane is lifted and pushed out, and the cylinder connection flange is placed in the pre-designed rail at the bottom of the furnace body to start the hydraulic pump station. , easily launch the lining. Reduced work intensity and improved work efficiency.

IF power performance characteristics:

According to the size of the power , the induction melting furnace can choose KGPS intermediate frequency power supply , 12 pulse wave intermediate frequency power supply and 24 pulse wave intermediate frequency power supply , and can also select IGBT intermediate frequency power supply . The control mode of the IF power supply can be designed as local control, touch screen control, remote control, and computer control.

Induction melting furnace technical parameters :

|

Induction melting furnace model |

GWGR - 1 |

GWGR -2 |

GWGR -3 |

|

Rated capacity (T) |

1 |

2 |

3 |

|

Power ( KW ) |

1000 |

1500 |

2000 |

|

Frequency ( Hz ) |

1000 |

800 |

800 |

|

Rated temperature (°C) |

1650 |

1650 |

1650 |

|

Melting time (minutes / furnace) |

60 |

60 |

80 |

|

Power consumption ( kwh/t ) |

550~600 |

550~600 |

550~600 |

|

Cooling water pressure |

0.2~0.3M p a |

0.2~0.3M p a |

0.2~0.3M p a |

|

Inlet water temperature (°C) |

≤ 35 |

≤ 35 |

≤ 35 |

|

Outlet water temperature (°C) |

≤ 55 |

≤ 55 |

≤ 55 |

Related Products:

1 ton induction melting furnace

2 tons induction melting furnace

3 tons induction melting furnace

5 tons induction melting furnace

手 机:15038554363