洛阳松导感应加热科技有限公司

联系方式:15038554363

24小时技术热线:15038554363

邮 箱:1390003299@qq.com

厂址:河南省洛阳市洛新工业园区

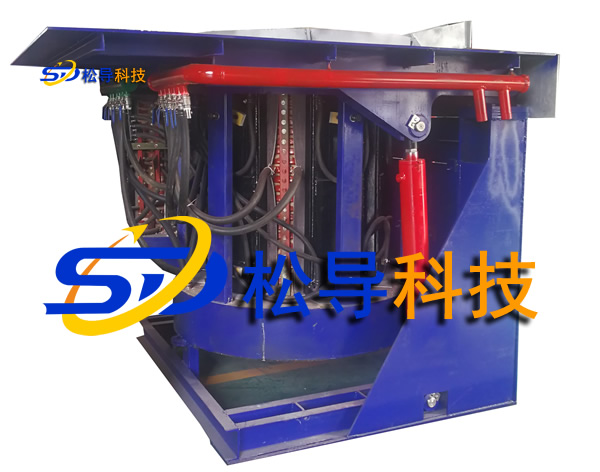

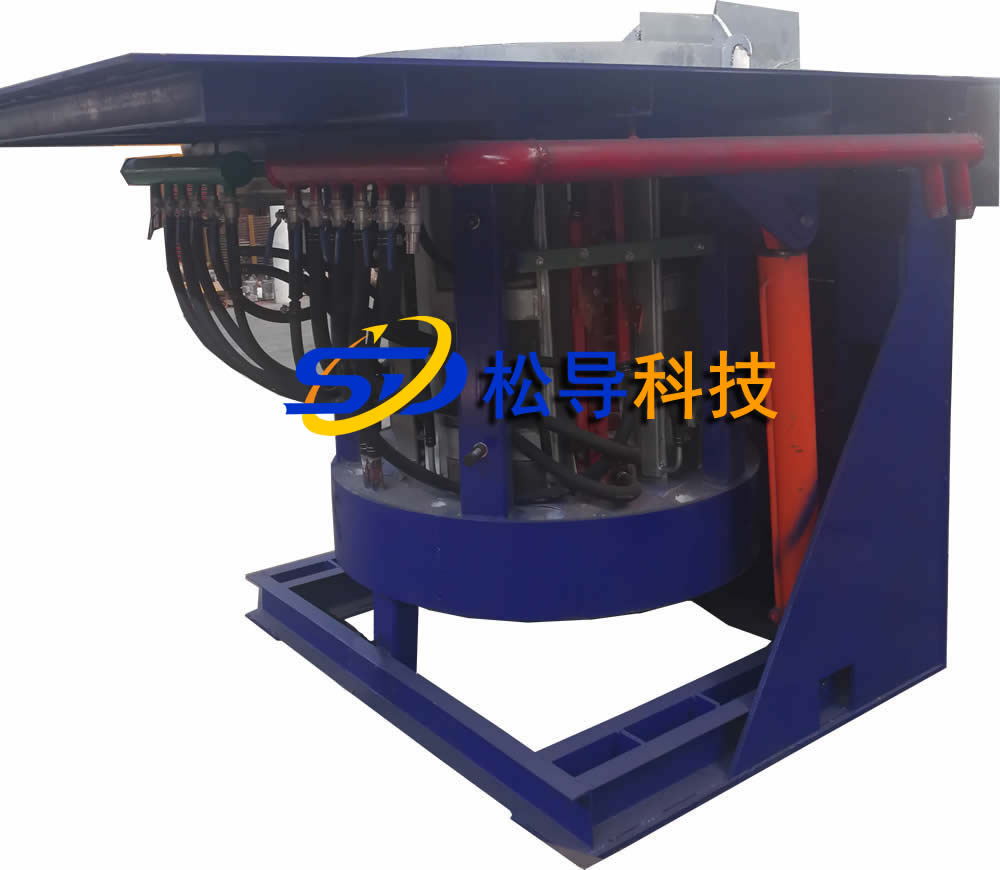

名称:0.5T中频炉2020新型

价格:0

0.5T中频炉2020新型

设备类型:

设备由并联谐振12脉中频电源和两台无芯钢壳感应熔化电炉以及系统正常运行所需的辅助设备组成。

0.5吨钢壳中频炉的主要工艺参数:

|

中 频 感 应 熔 炼 炉 |

额定容量 |

t |

0.5 |

|||

|

最大容量 |

t |

1 |

||||

|

出铁温度 |

℃ |

1450~1800 |

||||

|

熔化耗电量(热炉、钢水) |

kwh/t |

纯熔化的情况下570±5%。 |

||||

|

熔化耗电量(热炉、铁水) |

kwh/t |

纯熔化的情况下560±5%。 |

||||

|

熔化率(化钢水) |

h/t |

0.9 |

||||

|

冷 却 水 |

进水流量 |

m3/h |

≥40 |

|||

|

进水压力 |

MPa |

0.3 |

||||

|

进水温度 |

℃ |

≤32 |

||||

|

回水温度 |

℃ |

≤52 |

||||

|

倾炉方式 |

|

液压倾动 |

||||

|

|

||||||

|

整 流 变 压 器 |

产品型号 |

ZS-型 |

||||

|

电压组合 |

10KV/380V/380V 二次侧Δ/Y双绕组,星型绕组中点引出 |

|||||

|

变压器容量 |

KVA |

1000kva(两台共用) |

||||

|

一次电压 |

KV |

10±5%KV |

||||

|

二次电压 |

V |

380×2 |

||||

|

相数 |

一次侧3相; 二次侧6相接入中频电源柜 |

|||||

|

频率 |

HZ |

50 |

||||

|

联结组 |

DdOY11 (二次侧线电压相位互差30°) |

|||||

|

短路阻抗 |

≥ |

9% |

||||

|

冷却方式 |

ONAN,冷却介质:25号变压器油 |

|||||

|

调压方式 |

自动无励磁调压, |

|||||

|

效率 |

≥ |

98%, |

||||

|

执行标准 |

JB/T8636-1997《电力变流变压器》 |

|||||

|

整流变压器 整流变压器用于将一次高压电降到适合中频电源的输入电压,设备采用专用的高阻抗油浸自冷式整流变压器,其型号为ZS系列。变压器一次电压用10KV,二次电压380V。整流变压器上装有瓦斯继电器和油温继电器表,可与高压柜联锁,当变压器出现瓦斯或油温超标时,能自动切断高压输入并发出报警。 |

||||||

|

|

||||||

|

中 频 电 源

|

额定功率 |

KW |

500 |

|||

|

直流电压 |

V |

1024 |

||||

|

直流电流 |

A |

488 |

||||

|

整流脉数 |

脉 |

12 |

||||

|

冷 却 水 |

进水流量 |

m3/h |

≥15 |

|||

|

进水压力 |

MPa |

0.25 |

||||

|

进水温度 |

℃ |

≤32 |

||||

|

回水温度 |

℃ |

≤42 |

||||

|

中频电压 |

V |

2400 |

||||

|

中频频率 |

Hz |

800可微调 |

||||

|

功率因数 |

COSφ |

任何功率使用情况下≥0.95 |

||||

|

逆变形式 |

|

并联逆变 |

||||

|

噪音 |

dB |

85dB |

||||

|

起动成功率 |

|

100% |

||||

|

|

|

|

||||

|

|

|

|

||||

|

|

|

|

||||

|

|

|

|

|

|||

Energy-saving 0.5T induction melting furnace

Equipment type :

Device parallel resonant frequency pulse power supply 12 and two steel coreless induction melting furnace and auxiliary systems required for normal operation of the equipment.

0.5 tons of steel induction melting furnace main parameters:

|

in frequency sense should melt Refining furnace |

Rated Capacity |

t |

0.5 |

|||

|

Maximum capacity |

t |

1 |

||||

|

Iron temperature |

°C |

1450~1 8 00 |

||||

|

Melting power consumption (hot furnace, molten steel) |

Kwh/t |

570 ± 5% in the case of pure melting . |

||||

|

Melting consumption (heating furnace,molten iron) |

Kwh/t |

560 ± 5% in the case of pure melting . |

||||

|

Melting rate (steel steel) |

h/t |

0.9 |

||||

|

cold but water |

Influent flow |

M3/h |

≥ 40 |

|||

|

Inlet pressure |

MPa |

0.3 |

||||

|

Inlet temperature |

°C |

≤ 32 |

||||

|

Backwater temperature |

°C |

≤ 52 |

||||

|

Tilting method |

|

Hydraulic tilting |

||||

|

|

||||||

|

whole flow change Pressure Device |

Product number |

ZS -type |

||||

|

Voltage combination |

10KV/380V/380V Secondary side Δ /Y double winding, star winding midpoint extraction |

|||||

|

Transformer capacity |

KVA |

1000kva(two shared) |

||||

|

Primary voltage |

KV |

10 ± 5% KV |

||||

|

Secondary voltage |

V |

380 × 2 |

||||

|

Phase |

Primary side 3 phase ; secondary side 6 phase connected to intermediate frequency power supply cabinet |

|||||

|

frequency |

HZ |

50 |

||||

|

Connection group |

DdOY11 ( secondary side line voltage phase difference of 30° ) |

|||||

|

Short circuit impedance |

≥ |

9% |

||||

|

cooling method |

ONAN,cooling medium: 25thtransformer oil |

|||||

|

Pressure regulation method |

Automatic non-excitation voltage regulation , |

|||||

|

effectiveness |

≥ |

98%, |

||||

|

Executive standard |

JB/T8636-1997 "Power Converter Transformer" |

|||||

|

Rectifier transformer The rectifier transformer is used to reduce the primary high voltage to the input voltage suitable for the intermediate frequency power supply. The device uses a dedicated high-impedance oil-immersed self-cooling rectifier transformer, the model is ZS series. The primary voltage of the transformer is 10KV and the secondary voltage is 380V . The rectifier transformer is equipped with a gas relay and a oil temperature relay table, which can be interlocked with the high voltage cabinet. When the transformer has gas or oil temperature exceeding the standard, the high voltage input can be automatically cut off and an alarm is issued. |

||||||

|

|

||||||

|

in frequency Electricity source

|

rated power |

KW |

5 00 |

|||

|

DC voltage |

V |

102 4 |

||||

|

DC |

A |

488 |

||||

|

Number of commutating pulses |

pulse |

12 |

||||

|

cold but water |

Influent flow |

M3/h |

≥ 15 |

|||

|

Inlet pressure |

MPa |

0.25 |

||||

|

Inlet temperature |

°C |

≤ 32 |

||||

|

Backwater temperature |

°C |

≤ 42 |

||||

|

IF voltage |

V |

2400 |

||||

|

IF frequency |

Hz |

8 00 can be fine-tuned |

||||

|

Power factor |

C OSφ |

≥ 0.95 for any power usage |

||||

|

Inverter form |

|

Parallel inverter |

||||

|

noise |

dB |

85dB |

||||

|

Starting success rate |

|

100% |

||||

|

|

|

|

||||

|

|

|

|

||||

|

|

|

|

||||

|

|

|

|

|

|||

手 机:15038554363